Systems biologists and synthetic biologists spend a large amount of time moving small liquids from one vial to another. I would say it makes up the majority of their work day, even in a technologically cutting-edge lab which has robotics. Strange, isn’t it, that the most advanced biological science labs in the world are dependent on a human physically moving small drops of liquid samples and reagents around a lab?

Microfluidics aims to move liquids without humans, under computer control. A small flow of DNA in water, for example, might trace a path between two glass plates, within a tiny, etched microchannel. The movement of the flow is controlled by numerous micro-mechanical valves connected to electronics.

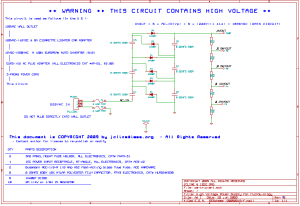

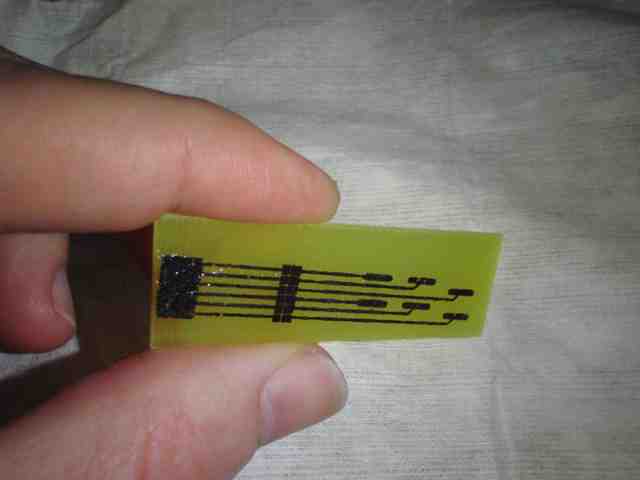

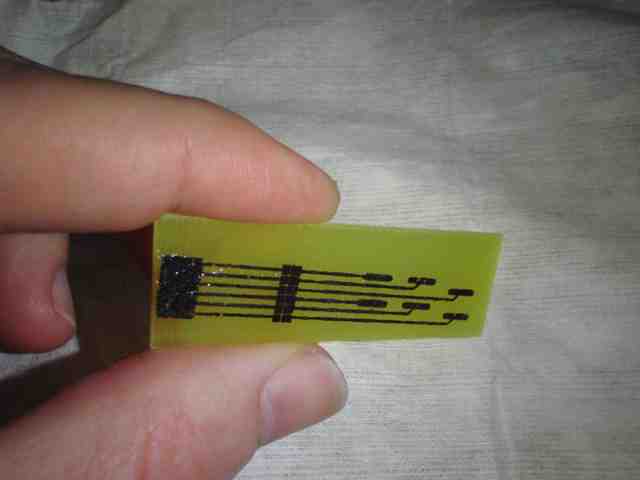

Digital microfluidics aims to move liquids without humans, under computer control, using only single droplets under electrical control: no micro-mechanical valves. It works by using electric fields (electrowetting-on-dielectric properties, abbreviated “EWOD”), which polarize water atoms enough to move a very small water droplet across the surface of a computer board. Droplets on the board can split into two, or join together into one.

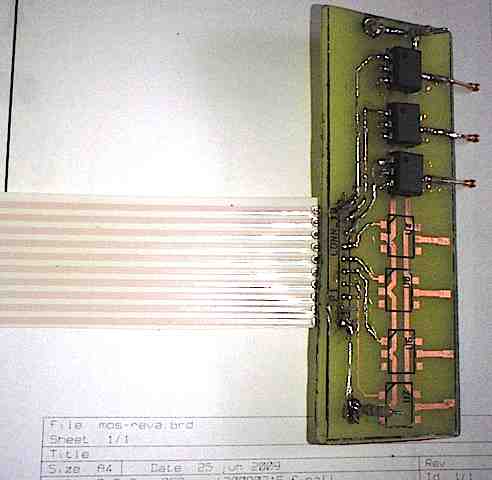

Standard PCB etching techniques can be used to make low-tech digital microfluidics devices

More→