A few years ago, some bright students at Texas A&M improved upon the most basic tool for manipulating microbiology: a thermocycler. Thermocyclers are typically large tabletop instruments which require a large sample, a lot of electrical power, and a lot of time to heat and cool. Alternatively, the process can be done by hand with a pot of boiling water, a bucket of cold water, a stopwatch, and a lot of free time and patience. The sample itself, for the purpose of “amplifying” the desired material in the sample, runs through many iterations of heat/cool cycling, such as the following:

- Denature: 95°C, 15 mins

Thermocycling

- No. of cycles: 39

- Denature: 94°C, 30 secs

- Anneal: 62°C, 30 secs

- Elongate: 68°C, 3.5 mins

Termination

- Elongate: 68°C, 20 mins

- Hold: 4°C, until removed from machine

The Texas team created a pocket-sized version, which could run on batteries as well, and most notably, was able to create a new patent. By creating a pocket-sized, battery powered device, the team accomplished several very important features:

- The device can be used easily at the point-of-care, as a field unit;

- The device is much lower engineering cost, and much lower patent royalty cost: from thousands of dollars down to hundreds of dollars;

- The device uses a much smaller sample, and has faster heat/cool times, thus reducing the experimental cost and experimental time.

This new thermocycler has created some excitement in the bio community for some time — however, it still took over a year to finish patent issues. The university owned the patent; they requested royalties, and up-front option fees, and meanwhile, the device itself remained in limbo. The great news is that the manufacturing prototype is announced (see below). The bad news is that such patent hassles are typical, and this was a simple case where a university owned the patent in whole rather than multiple holders owning the patent in part.

From the business angle, the thermocycler market is a billion-dollar market, since it is a fundamental tool for all microbiology or genetic engineering labs.

Some of original papers and articles for the “$5 thermocycler” are:

- Engaget: Mini DNA replicator costs $10 – May, 2007

- New Scientist: Mini DNA replicator could benefit world’s poor – May, 2007

- Angewandte Chemie: A Pocket-Sized Convective PCR Thermocycler – April, 2007

From Rob Carlson’s synthesis.cc blog:

This week Biodesic shipped an engineering prototype of the LavaAmp PCR thermocycler to Gahaga Biosciences. Joseph Jackson and Guido Nunez-Mujica will be showing it off on a road trip through California this week, starting this weekend at BilPil. The intended initial customers are hobbyists and schools. The price point for new LavaAmps should be well underneath the several thousand dollars charged for educational thermocyclers that use heater blocks powered by peltier chips.

The LavaAmp is based on the convective PCR thermocycler demonstrated by Agrawal et al, which has been licensed from Texas A&M University to Gahaga. Under contract from Gahaga, Biodesic reduced the material costs and power consumption of the device. We started by switching from the aluminum block heaters in the original device (expensive) to thin film heaters printed on plastic. A photo of the engineering prototype is below (inset shows a cell phone for scale). PCR reagents, as in the original demonstration, are contained in a PFTE loop slid over the heater core. Only one loop is shown for demonstration purposes, though clearly the capacity is much larger.

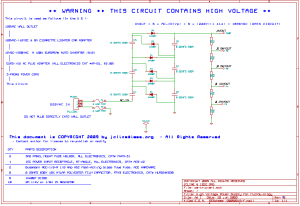

The existing prototype has three independently controllable heating zones that can reach 100C. The device can be powered either by a USB connection or an AC adapter (or batteries, if desired). The USB connection is primarily used for power, but is also used to program the temperature setpoints for each zone. The design is intended to accommodate additional measurement capability such as real-time fluorescence monitoring.

We searched hard for the right materials to form the heaters and thin film conductive inks are a definite win. They heat very quickly and have almost zero thermal mass. The prototype, for example, uses approximately 2W whereas the battery-operated device in the original publication used around 6W.

What we have produced is an engineering prototype to demonstrate materials and controls — the form factor will certainly be different in production. It may look something like a soda can, though I think we could probably fit the whole thing inside a 100ml centrifuge tube.

If I get my hands on one myself, I’ll post a review.