Systems biologists and synthetic biologists spend a large amount of time moving small liquids from one vial to another. I would say it makes up the majority of their work day, even in a technologically cutting-edge lab which has robotics. Strange, isn’t it, that the most advanced biological science labs in the world are dependent on a human physically moving small drops of liquid samples and reagents around a lab?

Microfluidics aims to move liquids without humans, under computer control. A small flow of DNA in water, for example, might trace a path between two glass plates, within a tiny, etched microchannel. The movement of the flow is controlled by numerous micro-mechanical valves connected to electronics.

Digital microfluidics aims to move liquids without humans, under computer control, using only single droplets under electrical control: no micro-mechanical valves. It works by using electric fields (electrowetting-on-dielectric properties, abbreviated “EWOD”), which polarize water atoms enough to move a very small water droplet across the surface of a computer board. Droplets on the board can split into two, or join together into one.

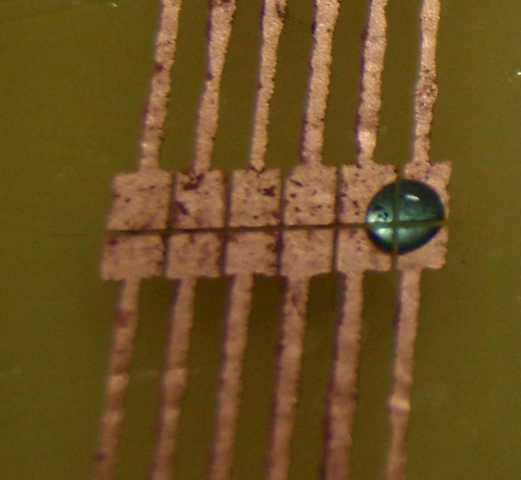

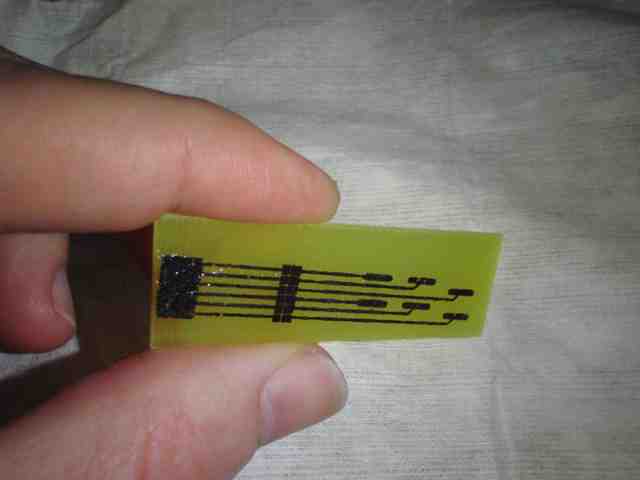

I fabricated a couple digital microfluidic devices recently. The fabrication can be DIY (skunkworks tech in the garage). There are dozens of papers on digital microfluidics (sometimes called “DMF”) in various journals. A droplet from a pipette can be moved across electrical contacts using medium-high voltage (400V to 700V) on a standard printed circuit board.

A small droplet of liquid, 0.5 to 1 uL, possibly containing biological reagents, can be moved under electonic control

Since the voltage is very high, my device (pictured) requires a bit of high voltage safety. I hope to get the working voltage within a reasonable range, so manipulation is easier, and add electronics for automated control. I’ll post more details as time permits. Eventually, completion of a biology protocol is possible: electronically “dispensing” droplets from reagent wells and sample wells, mixing them as necessary, heating or cooling for thermocycling PCR, detection with electronic sensors, and depositing into output or waste disposal wells. Then the biologists can spend more time on real problems, rather than moving liquids around from vial to vial!

“By using PC boards with different thicknesses of copper, structures on the finished PC boards with different heights can be easily produced. For example a 1 oz/ft^2 copper board will produce masters with structures approximately 34.3 µm height, while a 1/2 oz/ft^2 board should produce structures with a height of 17.2 µm. Similarly, a 4 oz/ft^2 copper board can be used to make structures with a height of 137 µm.” [1]

Very interested techies should search the web for the following: UCLA microfluidics, Duke University microfluidics, University of Toronto microfluidics.

[1] FABRICATION OF MASTERS FOR MICROFLUIDIC DEVICES USING

CONVENTIONAL PRINTED CIRCUIT TECHNOLOGY, Masters Thesis, ARJUN PENUBOLU SUDARSAN

Interesting subject..

In the picture you have 6 vertical electrodes ( horizontal spark gap brakes ), is the droplet of the fluid (blue droplet on the right) going to travel in the horizontal direction

when sequencing individual electrodes?

What fluids have you tested so far?

surface tension, viscosity challenges?

Thank you for yours comments.

Lou

Lou –

In the bottom picture, the droplet moves right to left.

The droplet can be any water solution. Also, water surrounded by oil also works in the research.

I will post another article with further details including circuit board layout files for easy fabrication.

[…] now tested the digital microfluidics board via microcontroller. The digital microfluidics board moves a liquid droplet via Electrowetting-on-Dielectric (EWOD). The microcontroller switches the […]

Jonathan, what are the pad and trace sizes you used as well as the gap between the pads?

Thanks, Bruce

1mm x 1mm pads with 0.5mm gap (or smaller). Though, tried a bunch of different combinations there. The pad size is related to droplet size ( 1 uL of water being well suited to 1.5mm pad size or so). Gap width should be minimized as much as possible without causing shorts or sparks. Sparking can be a big problem.